A 200 tph (tons per hour) stone cone crusher is a robust piece of equipment designed for high-capacity crushing applications. The price of such a machine can vary widely depending on several factors including brand, quality, features, and regional market conditions. Here’s a detailed look at what influences the price of a 200 tph stone cone crusher:

1. Brand and Manufacturer

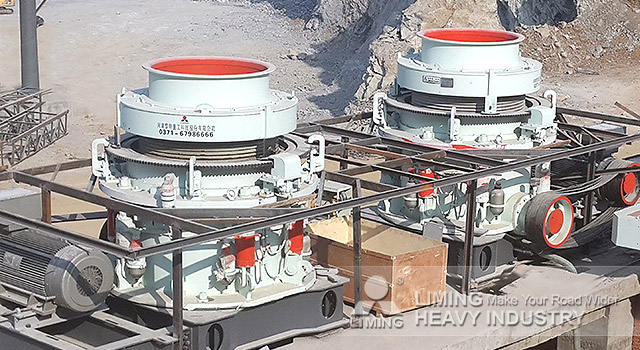

The brand of the cone crusher significantly impacts its price. Reputable brands with a strong track record for reliability and performance tend to command higher prices. Well-known manufacturers often offer advanced technology, better after-sales support, and more durable machinery, which can justify the higher cost.

2. Quality and Material

The quality of materials used in the construction of the cone crusher affects its price. High-grade materials and components contribute to the durability and efficiency of the machine, potentially increasing its cost. Premium crushers with advanced features like high chrome alloy liners, hydraulic adjustment systems, and advanced automation controls are usually priced higher.

3. Features and Specifications

Cone crushers come with various features such as hydraulic adjusters, advanced lubrication systems, and automation controls. A 200 tph cone crusher equipped with state-of-the-art technology and features will be priced higher than a more basic model. Features that enhance operational efficiency, reduce maintenance needs, and improve overall performance add to the cost.

4. Regional Market Conditions

Prices can also vary depending on the region due to factors such as shipping costs, local taxes, and import duties. In some countries, the cost of importing heavy machinery can significantly increase the final price. Additionally, local competition and availability of spare parts can influence pricing.

5. Production Capacity and Efficiency

The production capacity of the crusher and its efficiency are key factors in determining its price. A 200 tph cone crusher that delivers consistent performance and high throughput will be priced higher than models with lower efficiency or capacity. Crushers that are designed for high performance and can handle challenging materials tend to have a premium price.

6. Customization and Optional Add-ons

Custom-built or modified crushers that meet specific requirements or include optional add-ons will also affect the price. Customizations might include specialized liners, unique feed and discharge arrangements, or integration with other equipment in a crushing plant.

7. After-Sales Support and Warranty

Comprehensive after-sales support and warranty packages can influence the overall cost. Manufacturers offering extended warranties and reliable support services may charge more upfront, but this can provide added value and peace of mind in the long run.

When considering the purchase of a 200 tph stone cone crusher, it’s essential to evaluate the specific needs of your operation, including capacity, efficiency, and additional features. While the initial investment can be substantial, selecting a high-quality, well-supported machine can lead to improved performance and reduced operational costs in the long term. Always ensure to conduct thorough research, compare options, and consult with suppliers to find the best value for your investment.