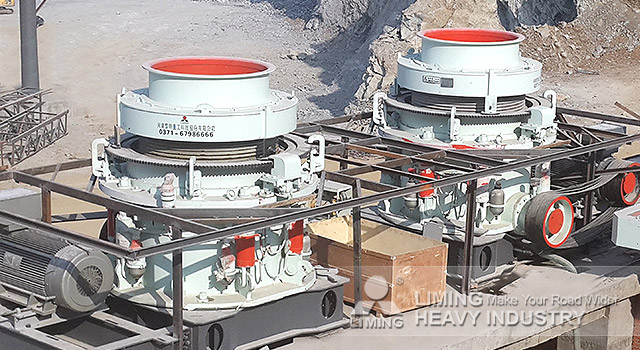

Cone crushers are widely used in the mining and aggregate industries due to their ability to crush a variety of materials, including hard and abrasive ones. Ensuring safety and effective maintenance is crucial to the optimal performance and longevity of these machines. Here’s an overview of safety practices and maintenance guidelines for cone crushers.

Safety Practices

- Personal Protective Equipment (PPE): Operators and maintenance personnel should always wear appropriate PPE, including helmets, safety glasses, gloves, and hearing protection. These items protect against potential hazards such as falling objects, flying debris, and loud noise.

- Training and Procedures: Only trained personnel should operate or maintain cone crushers. Comprehensive training programs should cover safe operating procedures, emergency shutdown protocols, and proper handling of tools and equipment.

- Lockout/Tagout (LOTO): Implement lockout/tagout procedures to ensure that the crusher is de-energized and cannot be started while maintenance is being performed. This helps prevent accidental startup that could result in injury.

- Guarding and Safety Devices: Ensure that all safety guards and protective devices are in place and functioning correctly. These include guards around the drive belts, pulleys, and moving parts. Safety devices like emergency stop buttons should be easily accessible and operational.

- Inspection Before Operation: Perform a pre-operation inspection to check for any signs of wear or damage. Inspect hydraulic systems, electrical connections, and wear parts to ensure they are in good condition before starting the machine.

Maintenance Guidelines

- Regular Inspections: Conduct regular inspections of the cone crusher to identify any signs of wear or potential issues. Key components to check include the crushing chamber, mantle, concave liners, and hydraulic system. Look for signs of excessive wear, cracking, or misalignment.

- Lubrication: Proper lubrication is critical for the smooth operation of the cone crusher. Regularly check and maintain the lubrication system to ensure that bearings and other critical components receive the necessary lubrication. Follow the manufacturer’s recommendations for lubricant type and intervals.

- Adjustments and Settings: Regularly check and adjust the crusher settings to ensure optimal performance. This includes adjusting the crusher gap, feed rate, and discharge settings. Proper adjustment helps maintain product size and shape, and reduces unnecessary wear on components.

- Cleaning and Debris Removal: Keep the crusher and its surroundings clean. Remove any built-up debris, such as dust and dirt, which can affect performance and lead to overheating. A clean machine is less likely to experience overheating and mechanical issues.

- Replacement of Worn Parts: Replace worn or damaged parts promptly to prevent further damage and maintain efficient operation. Commonly replaced parts include liners, mantles, and hydraulic components. Use genuine parts recommended by the manufacturer to ensure compatibility and performance.

- Hydraulic System Maintenance: Regularly check the hydraulic system for leaks, pressure consistency, and fluid levels. Hydraulic systems are crucial for adjusting the crusher’s settings and for proper operation, so maintaining them is essential for overall performance.

Effective safety practices and regular maintenance are vital to ensuring the reliable operation and longevity of cone crushers. By adhering to these guidelines, operators can reduce the risk of accidents, minimize downtime, and maintain optimal performance. Regular training and adherence to manufacturer recommendations further enhance safety and efficiency in cone crusher operations.