There are several types of rock crushers, each type of rock crusher is suited for specific materials and desired output sizes, allowing professionals to select the best fit for their needs. Common types include jaw crushers, cone crushers, impact crushers, gyratory crushers, and hammer crushers, each designed for different applications and materials.

Jaw crushers are one of the most widely used rock crushers, particularly suited for crushing large and hard rocks. They operate by using two plates, one fixed and one that moves back and forth, creating a compressive force that breaks down rocks into smaller pieces. Known for their durability and simple structure, jaw crushers are favored for primary crushing in mining and quarrying, handling a wide range of materials, including granite, basalt, and iron ore. They are also relatively easy to maintain, making them a popular choice for long-term projects.

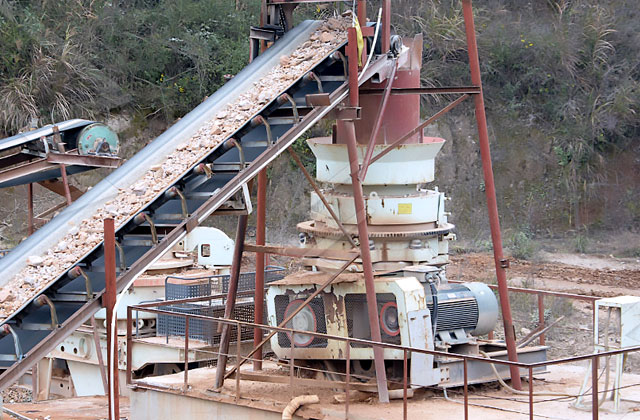

Cone crushers are another popular choice, especially effective for secondary and tertiary crushing stages. They consist of a rotating cone inside a concave chamber, where the material is crushed by compression between the cone and chamber walls. Cone crushers are highly efficient for crushing harder materials like granite and basalt, producing a fine, uniform output. They offer high productivity and are frequently used in aggregate production, mining, and even recycling applications due to their ability to handle abrasive materials.

Impact crushers utilize a different approach by breaking rocks through high-speed collisions. They consist of a rotor with hammers or blow bars that throw the material against impact plates, shattering it into finer particles. Known for producing high-quality, cube-shaped aggregates, impact crushers are commonly used for softer materials like limestone but can also handle certain harder stones. This type is popular for concrete recycling and road construction projects where a specific shape and size of the final product are essential.

Gyratory crushers are heavy-duty machines used primarily for large-scale mining and quarrying. They work similarly to cone crushers but have a larger opening and a conical head that gyrates within a circular crushing chamber. Gyratory crushers are ideal for continuous, high-capacity crushing and are used in primary crushing for particularly hard materials, such as ores. Due to their large size and operational requirements, these crushers are usually found in fixed plants rather than mobile configurations.

Each rock crusher type offers unique advantages, and choosing the right one depends on factors like material type, project requirements, and production goals. Jaw and gyratory crushers excel in primary crushing, cone crushers in secondary or tertiary stages, and impact crushers where shape quality is paramount. By understanding the strengths of each type, professionals can better plan and execute their crushing projects, ensuring efficiency, productivity, and desired output.