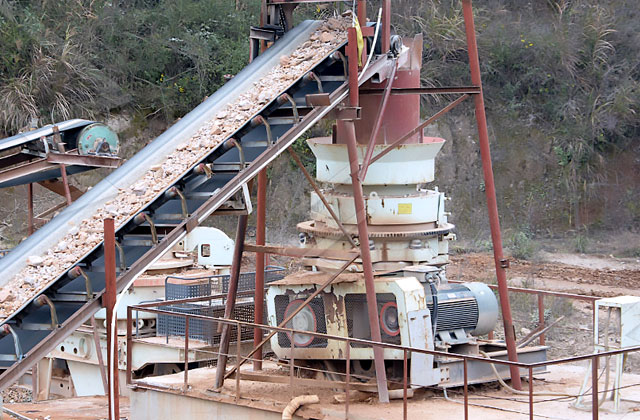

A granite cone crusher is a crucial piece of equipment in the mining and construction industries. It is designed to break down large chunks of granite into more manageable pieces that can be used in various construction projects or for other industrial applications. Here’s a detailed overview of what a granite cone crusher is, how it works, and its benefits:

Introduction to Granite Cone Crusher

A granite cone crusher is a type of secondary and tertiary crushing equipment used in granite processing plants. It operates by compressing granite ore between a mantle and a concave. The mantle is mounted on a vertical shaft and revolves eccentrically within the concave, which is fixed on the main frame of the crusher.

Components of a Granite Cone Crusher

- Main Frame: The main frame of the cone crusher supports all the components and maintains the structural integrity of the machine.

- Mantle and Concave: These are the crushing surfaces of the cone crusher. The mantle is mounted on the main shaft and gyrates eccentrically within the concave.

- Drive Mechanism: Typically, cone crushers are powered by electric motors or diesel engines that drive the eccentric shaft to rotate the mantle.

- Adjustment Ring: This component allows for adjustment of the crusher setting to achieve the desired product size.

- Feed Hopper: Granite ore is fed into the crusher through a feed hopper, which directs the material into the crushing chamber.

How a Granite Cone Crusher Works

- Crushing Process: Granite ore enters the crushing chamber through the feed hopper and is impacted by the mantle as it gyrates within the concave. This process breaks the granite into smaller pieces.

- Size Reduction: The crushed granite pieces fall through the narrow opening between the mantle and concave. The size of the final crushed product is determined by the setting of the crusher.

- Efficiency and Productivity: Cone crushers are known for their efficiency in crushing hard and abrasive materials like granite. They can produce uniform-sized finished products and are widely used in secondary and tertiary crushing stages.

Benefits of Using a Granite Cone Crusher

- High Productivity: Cone crushers can handle large volumes of granite ore, making them suitable for high-capacity applications in mining and construction.

- Versatility: They can crush various types of granite, ranging from standard to extra-coarse, depending on the crushing chamber configuration.

- Reliability: Modern cone crushers are designed with robust materials and components, ensuring reliable operation and minimal downtime.

- Cost-effectiveness: While initial investment costs may be higher compared to some other types of crushers, cone crushers offer lower operating costs over the long term due to their efficiency and durability.

Market Overview and Considerations

In the market for granite cone crushers, buyers should explore various suppliers and manufacturers to compare features, pricing, and after-sales support. Factors such as warranty, service contracts, and customer reviews are crucial in making an informed purchase decision. Additionally, consulting with industry experts and reviewing technical specifications can provide valuable insights into choosing the right equipment for specific applications.

Granite cone crusher is a versatile and efficient piece of equipment that plays a crucial role in the processing of granite ore in various industries. Its ability to crush hard and abrasive materials efficiently makes it indispensable in mining and construction applications. Whether for producing aggregates or preparing material for further processing, a granite cone crusher offers reliability, productivity, and cost-effectiveness.