If you’re in the market for a granite processing crusher, there are a few key factors to consider. These crushers are designed to handle and process granite, a very hard and dense material, which makes them crucial for producing high-quality crushed granite products. If you’re looking to buy a granite processing crusher, here’s an overview of what you need to know:

Types of Granite Crushers

- Jaw Crushers: These are typically used as primary crushers for granite processing. They work by compressing the granite between a stationary jaw and a moving jaw. The result is a coarse, broken-down material that can be further processed. Jaw crushers are known for their robust construction and high capacity, making them ideal for large-scale operations.

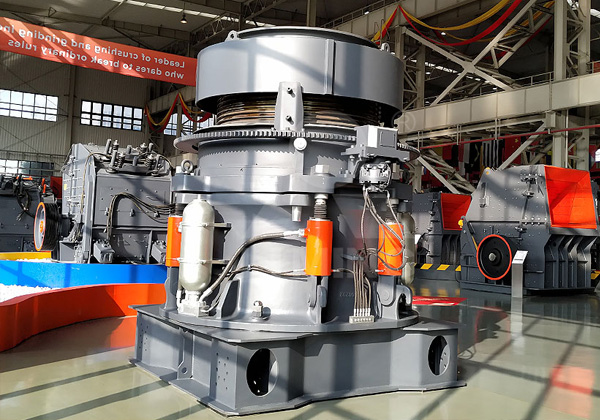

- Cone Crushers: After the initial crushing by a jaw crusher, cone crushers are often used for secondary or tertiary crushing. They operate by compressing the granite between an eccentric rotating spindle and a concave surface. Cone crushers are well-suited for producing finer materials and can handle high volumes of feed.

- Impact Crushers: These crushers use impact force to break down granite. They can be effective for both primary and secondary crushing. The material is thrown against a high-speed rotor and is shattered by the impact. Impact crushers are often used to create a more uniform particle size and are useful for making sand and aggregate.

- Vertical Shaft Impact (VSI) Crushers: VSI crushers use a high-speed rotor to create impact forces that break the granite. They are particularly effective for producing fine aggregates and sand, making them a popular choice for high-quality granite processing.

Key Features to Look For

- Durability and Build Quality: Granite processing crushers should be built to withstand heavy loads and harsh working conditions. Look for crushers made from high-quality materials such as manganese steel for the jaws and alloy steel for other components.

- Capacity: This refers to the amount of granite the crusher can process per hour. Depending on your production needs, you should choose a crusher with a capacity that meets your requirements.

- Size and Output: Granite crushers come in various sizes, and the size of the crusher you choose will affect the output size of the granite. Ensure that the crusher can produce the size and quality of granite you need for your application.

- Durability and Maintenance: Granite processing can be tough on machinery, so durability is crucial. Look for crushers made from high-quality materials and those that offer easy maintenance and spare parts availability.

Importance of choosing a granite crusher

Choosing the right granite processing crusher involves understanding your specific needs and evaluating different options based on durability, efficiency, and cost. By considering these factors and sourcing from reputable suppliers, you can ensure that you select a crusher that will meet your production demands and deliver long-term performance.