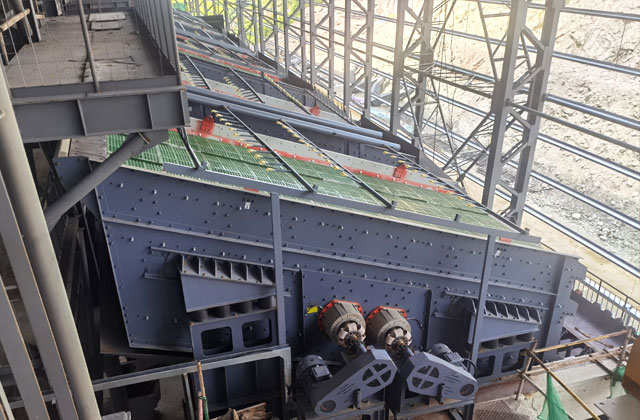

A mineral aggregate vibrating screen is a crucial piece of equipment in various industries, including mining, construction, and mineral processing. It is used to separate, classify, and dewater granular materials. These screens are designed to handle large volumes of material with high efficiency and precision, making them essential for optimizing production processes and ensuring product quality.

Working Principle

The working principle of a mineral aggregate vibrating screen is relatively straightforward. When the machine is powered on, the motor generates oscillations. These oscillations are transferred to the screening surface, causing the material to move in a controlled manner. Smaller particles fall through the mesh openings, while larger particles move to the end of the screen and are discharged. The angle of the screen and the vibration amplitude can be adjusted to optimize the screening process for different materials and sizes.

Features and Benefits

- High Efficiency and Capacity: Modern vibrating screens are engineered to handle substantial throughput, ensuring that large quantities of material can be processed quickly. The high-frequency vibrations facilitate rapid and efficient separation of different sized particles.

- Versatile Applications: These screens are versatile and can be used in various applications, including mineral processing, coal mining, sand and gravel processing, and recycling operations. They are capable of handling a wide range of materials, from fine sand to large rocks.

- Robust Construction: Built with durable materials, mineral aggregate vibrating screens are designed to withstand harsh operating conditions. Heavy-duty construction ensures long-term reliability and reduces the need for frequent maintenance.

- Precision Screening: Advanced design features, such as adjustable screen angles and multiple screen decks, allow for precise control over the screening process. This ensures that the final product meets specific size and quality requirements.

- Energy Efficiency: Newer models of vibrating screens are designed to be energy-efficient, reducing operational costs while maintaining high performance. This is achieved through advanced engineering and the use of energy-efficient motors.

- Easy Maintenance: Many vibrating screens feature modular components and user-friendly designs that make maintenance and repair straightforward. This minimizes downtime and ensures that the equipment remains in optimal working condition.

Considerations When Buying

When purchasing a mineral aggregate vibrating screen, several factors need to be considered to ensure the machine meets your needs:

- Capacity: Ensure the screen can handle the required throughput.

- Material: The construction material should be compatible with the type of material being processed.

- Size: The screen size should match the size of the material being sorted.

- Mesh Type: The mesh opening size should be suitable for the desired particle size distribution.

- Durability: Consider the robustness of the frame and components to ensure longevity.

Investing in a high-quality mineral aggregate vibrating screen can significantly enhance the efficiency and productivity of your material processing operations. With features such as high screening efficiency, robust construction, adjustable amplitude and frequency, and multiple deck configurations, these screens offer numerous benefits, including improved product quality, increased throughput, reduced operational costs, and versatility. With the right vibrating screen, operations can achieve higher efficiency, better product quality, and reduced operational costs.