A vertical shaft impact (VSI) crusher is a widely utilized equipment in the mining and construction industries. When it comes to river pebbles, which are naturally occurring stones with a smooth surface and high hardness, VSI crushers are particularly effective. They are designed to transform large, coarse pebbles into fine aggregates and sand, providing a high-quality, consistent product ideal for various construction applications.

Principle of Operation

The operation of a VSI crusher is based on the principle of impact crushing. Unlike traditional crushers that use compression to break down materials, VSI crushers leverage the power of impact. The river pebbles are fed into the crusher through a centrally located feed tube and are hurled against the crusher’s rotor. The rotor, spinning at high speeds, flings the pebbles against the chamber walls where they break upon impact. This process can be repeated until the desired size of the material is achieved.

Design and Functionality

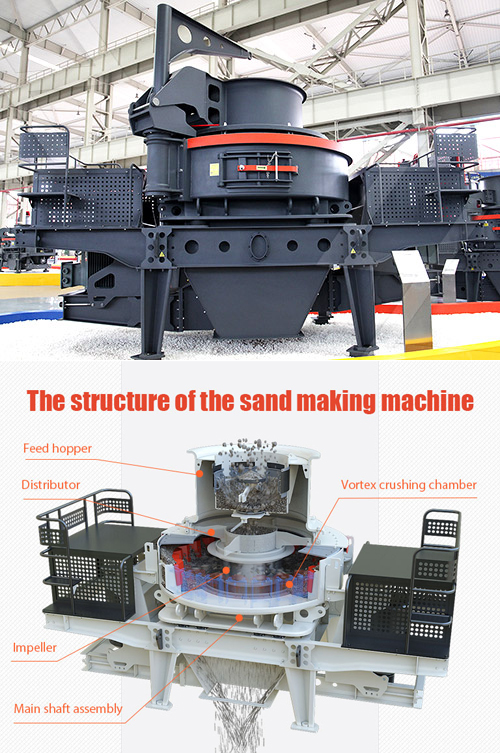

Vertical Shaft Design: The VSI crusher is characterized by a vertical shaft that houses the rotor, which spins at high speeds. The rotor’s role is to propel incoming materials against the crusher’s anvils or impact plates, causing them to break into smaller particles. This design is highly effective for river pebbles, which are typically rounded, hard, and abrasive, making them challenging to crush with traditional methods.

Impact Mechanism: When river pebbles enter the crusher, they are accelerated by the spinning rotor and hurled at high speeds against the stationary anvils. The impact force shatters the pebbles into smaller fragments. Additionally, the VSI crusher may use a rock-on-rock crushing action, where the material collides with other particles, further enhancing the reduction process and improving the product’s shape and consistency.

Adjustability and Flexibility: The VSI crusher allows for adjustments in the speed of the rotor and the configuration of the anvils, providing operators with the flexibility to tailor the crushing process to the specific characteristics of the river pebbles being processed. This adaptability ensures optimal performance, whether the goal is to produce coarse aggregates or fine sand.

Advantages of Using VSI Crushers for River Pebbles

- High-Quality Product: VSI crushers produce well-shaped, fine aggregates that are highly sought after in concrete production and road construction. The shape of the aggregate is crucial for the strength and durability of concrete.

- Efficiency: The VSI crusher is highly efficient, capable of processing large volumes of river pebbles in a relatively short time. This efficiency translates into lower operational costs and higher output rates.

- Versatility: These crushers can handle a wide range of material sizes and hardness, making them suitable for other applications beyond river pebbles, such as limestone, granite, and basalt. This versatility makes them suitable for different stages of the crushing process, from primary to tertiary crushing.

- Production of High-Quality Sand: The VSI crusher excels in producing manufactured sand, which is increasingly in demand for concrete production. The finely crushed sand has excellent properties, such as good particle shape, gradation, and cleanliness, making it a viable alternative to natural sand.

Maintenance and Operation

Maintaining a VSI crusher is straightforward, with easy access to wear parts and a simplified design that facilitates quick replacement and minimal downtime. Regular inspections and timely replacement of worn components ensure optimal performance and longevity of the equipment.

Operators should be trained to understand the crusher’s working principles, safety protocols, and maintenance procedures to maximize efficiency and safety. Automated control systems and monitoring tools are available to assist in managing the crusher’s performance and operational parameters.

The vertical shaft impact crusher is an invaluable asset in processing river pebbles and other natural aggregates. Its ability to produce high-quality, well-shaped materials efficiently and economically makes it a preferred choice in various construction and industrial applications. By investing in a VSI crusher, industries can enhance their production capabilities, reduce operational costs, and promote sustainable practices in aggregate processing.