A vibrating screen is an essential piece of equipment in the aggregate processing industry, particularly for screening and classifying materials like sand, gravel, crushed stone, and mineral ores. Its primary function is to separate materials of different sizes through vibrations that cause the particles to move and either pass through the screen or stay on top, depending on their size. The efficiency of the screen significantly impacts the overall output quality and operational performance of aggregate production plants.

Types of Vibrating Screens for Aggregate Screening

Vibrating screens come in several types based on the method of vibration, screen deck configuration, and the nature of materials processed. Common types include:

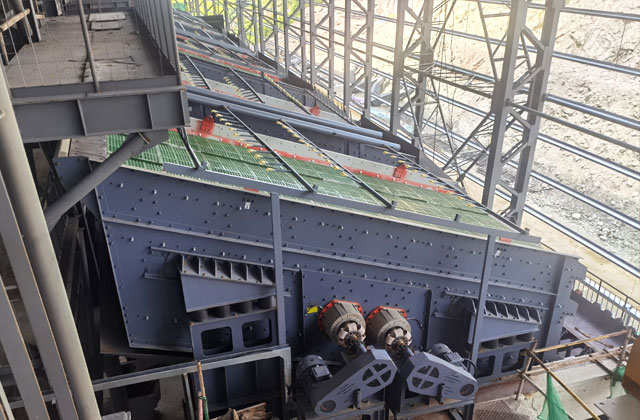

- Inclined Vibrating Screens: These screens are mounted at an angle, typically between 15° to 30°, to use gravity to assist in the screening process. As materials are fed onto the screen, they move downward due to the inclination, while the vibrating action helps in separating different particle sizes. Inclined screens are generally used in aggregate production for primary and secondary screening.

- Multi-Deck Screens: These screens feature multiple layers or decks, each with a different size aperture. Materials pass through successive layers, with each deck further refining the size distribution. This multi-layer design increases efficiency by allowing different sizes to be screened simultaneously.

- Circular Vibrating Screens: Circular motion vibrating screens operate by rotating the eccentric weight to create a circular vibration motion. They are commonly used in aggregate screening due to their ability to handle larger materials and provide effective screening performance.

Working Principle

The vibrating screen works by utilizing vibratory motors that generate linear or elliptical motion to shake the material on the screen surface. The vibration causes the particles to move across the screen, with the finer material passing through the screen’s openings while the larger particles stay on top. The key factors that influence the screen’s efficiency include the amplitude of the vibration, the frequency of the vibration, the angle of inclination, and the mesh size of the screen.

The screening process begins by feeding the aggregate material onto the screen deck. As the deck vibrates, the material is stratified, meaning that smaller particles tend to move downward through the layers of material on the screen, increasing the likelihood that they will pass through the mesh openings. The larger particles remain on the top and are discharged at the end of the screen.

Factors Affecting Vibrating Screen Efficiency

- Screen Mesh Size: The size of the openings in the screen is a critical factor in determining the efficiency of the screening process. The smaller the mesh size, the finer the material that can pass through. However, screens with very fine meshes are prone to clogging when screening sticky or wet materials.

- Vibration Amplitude and Frequency: The amplitude and frequency of the vibration affect the stratification of the material and the speed at which it moves across the screen. Higher amplitudes can help dislodge particles stuck in the screen and improve overall throughput, but they may also lead to excessive wear and tear.

- Material Characteristics: The nature of the material being screened—its size, moisture content, and abrasiveness—affects the screen’s performance. Sticky materials may cause clogging, while abrasive materials may lead to increased wear on the screen deck.

- Deck Angle: The inclination of the screen affects the rate at which material flows over the screen. Steeper angles increase throughput but reduce screening efficiency, while lower angles improve the separation but reduce the speed of material movement.

A vibrating screen is indispensable in the aggregate industry for separating and grading materials. Its versatility allows it to handle various types of materials, and its efficiency ensures that only materials of the desired size pass through. By optimizing factors like vibration amplitude, screen angle, and mesh size, producers can ensure high productivity and minimal downtime in aggregate processing operations.