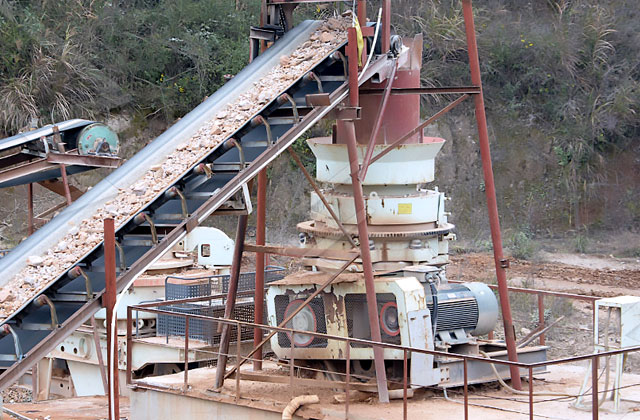

Overview of the Quarry Cone Crusher Market

The quarry cone crusher market plays a crucial role in the broader mining and construction industries, offering specialized equipment that crushes hard and abrasive materials such as granite, basalt, and iron ore. With rising urbanization and industrialization, the demand for construction materials has surged, propelling the growth of the quarry cone crusher market. This piece provides an in-depth analysis of the market dynamics, factors influencing the price of quarry cone crushers, and the projected trends.

Market Dynamics

- Demand from Construction and Mining Sectors: The primary driver for the quarry cone crusher market is the demand from the construction and mining industries. As construction projects and mining operations expand, the need for efficient and reliable crushers increases. This demand is especially prominent in emerging economies where infrastructure development is a priority.

- Technological Advancements: Innovation in crusher technology has significantly influenced the market. Manufacturers are increasingly focusing on developing advanced cone crushers that offer higher efficiency, reduced energy consumption, and enhanced durability. These advancements, while improving operational efficiency, also impact the pricing structure of the crushers.

- Environmental Regulations: Stricter environmental regulations have led to the development of eco-friendly crushers. These crushers, designed to minimize dust and noise pollution, often come at a higher price due to the additional technology and materials required to meet environmental standards.

Factors Influencing the Price

- Brand and Manufacturer: The brand and reputation of the manufacturer play a significant role in determining the price of a quarry cone crusher. Established brands with a history of producing reliable and efficient crushers often command higher prices due to their proven track record and customer trust.

- Crusher Capacity and Specifications: The capacity of the cone crusher, which is typically measured in tons per hour, is a crucial factor in its pricing. Crushers with higher capacities and more advanced specifications, such as automated control systems, tend to be more expensive. Additionally, the materials used in construction (e.g., high-grade steel) also influence the cost.

- Maintenance and Operating Costs: The total cost of ownership of a quarry cone crusher is not limited to the initial purchase price. Maintenance and operating costs, including wear and tear of parts, fuel consumption, and energy efficiency, also affect the overall expenditure. Crushers that are designed to minimize these costs may have a higher upfront price but offer long-term savings.

Future Trends

The quarry cone crusher market is expected to continue growing, driven by the ongoing demand for construction materials and the expansion of mining activities. Technological advancements, particularly in automation and AI integration, are likely to further influence the market, potentially driving up prices for the most advanced models. Additionally, as environmental concerns grow, the demand for eco-friendly crushers is expected to increase, further shaping the market dynamics.

The quarry cone crusher market is a dynamic and essential component of the mining and construction industries. While prices can vary widely depending on various factors, the overall trend is towards more efficient, durable, and environmentally friendly crushers. As the market evolves, operators will need to carefully consider their specific needs and the total cost of ownership when selecting a quarry cone crusher, balancing upfront costs with long-term operational efficiency.